Small Metal Injection Molding (MIM)

The featured process covers feedstock mixing, injection, debinding, sintering, secondary machining, and inspection. It supports intricate geometries with tight tolerances.

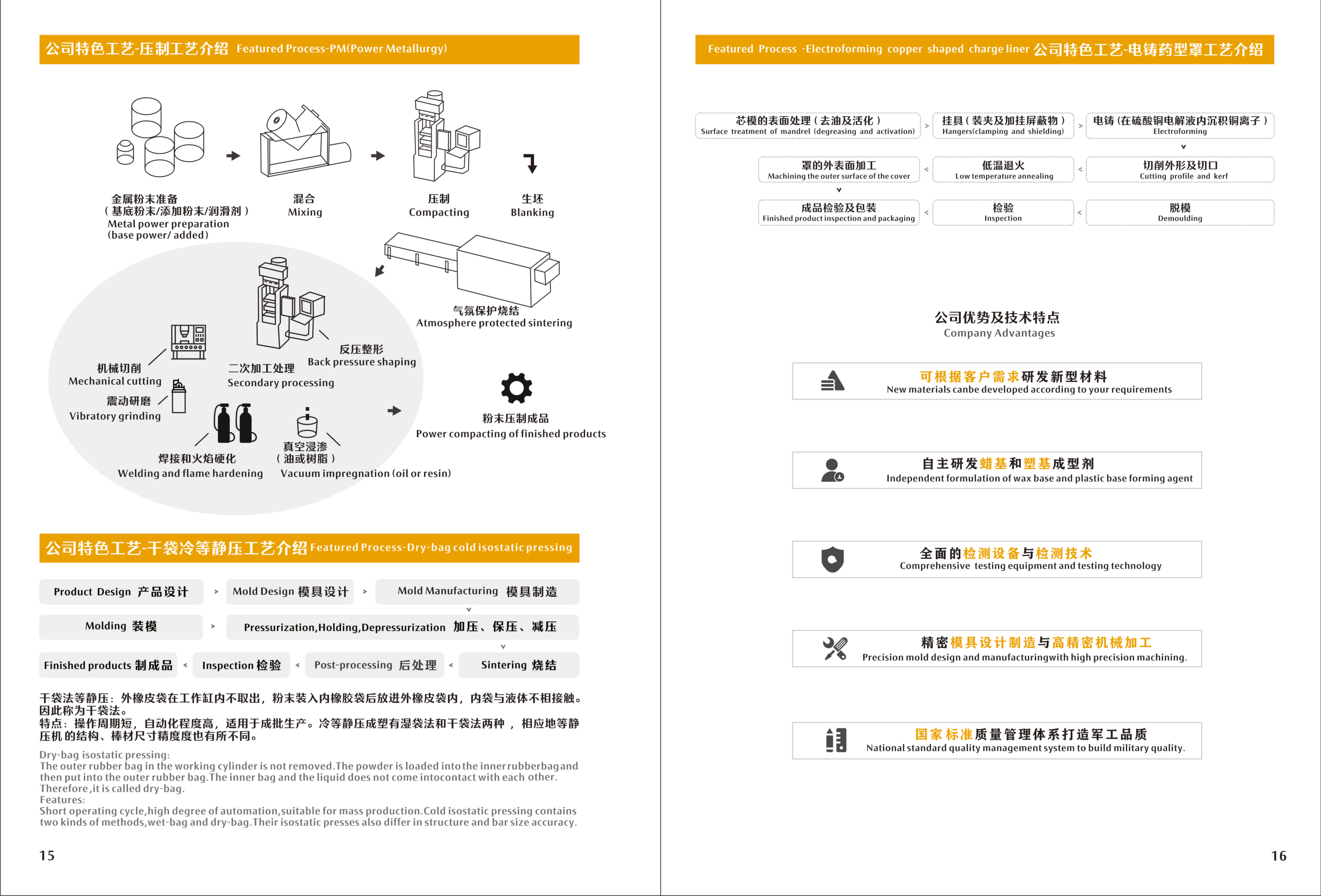

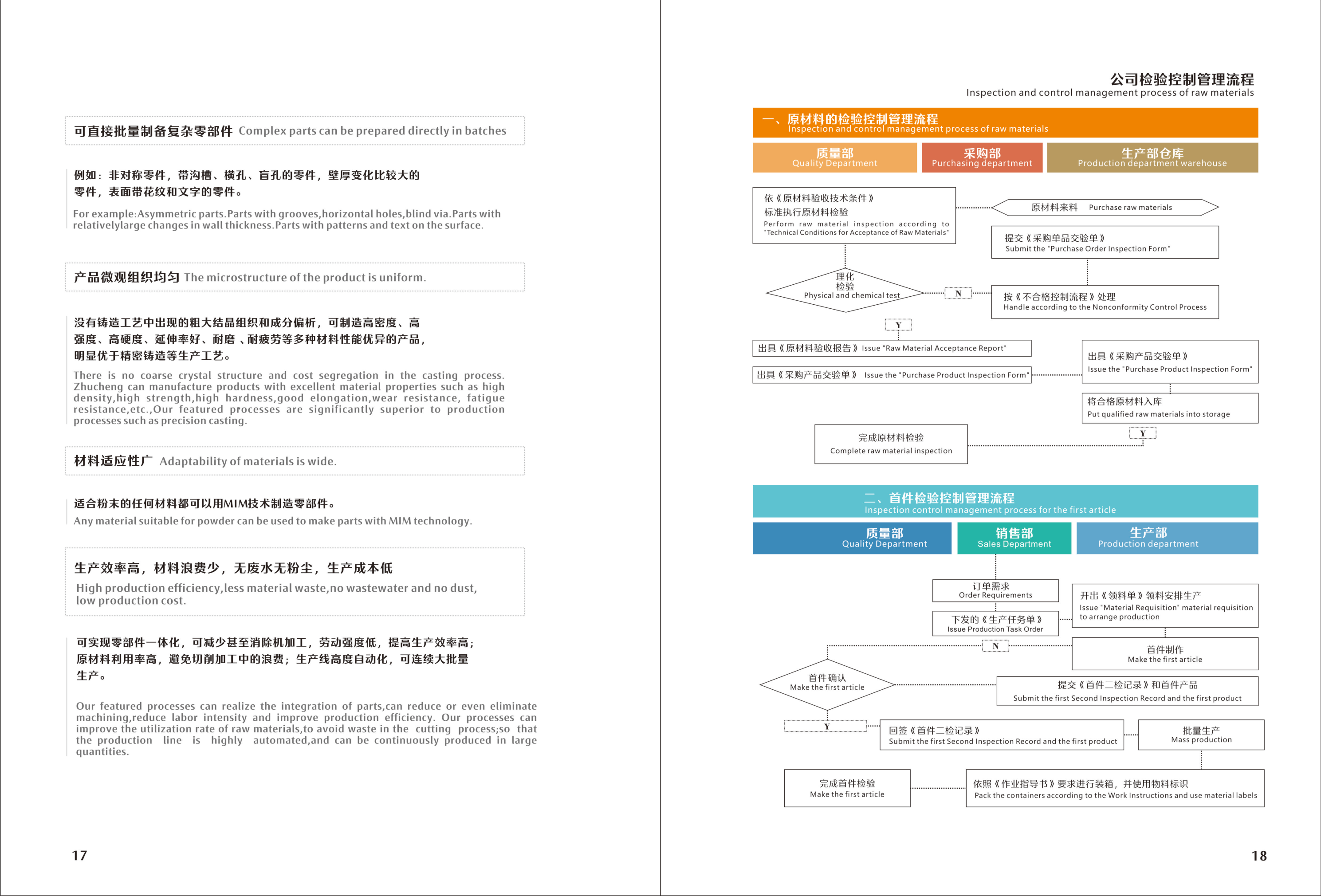

Process flow diagrams illustrate each stage from material prep to inspection, mirroring the brochure's bilingual visuals.

The featured process covers feedstock mixing, injection, debinding, sintering, secondary machining, and inspection. It supports intricate geometries with tight tolerances.

High-density tungsten and composite parts rely on staged pressing, sintering, infiltration, and sizing to achieve mechanical performance goals.

Hybrid processes combine injection forming with infiltration for multi-material solutions suitable for thermal management and wear-resistant assemblies.