Precision Metal PartsMIM • Powder Metallurgy • CNC

OEM/ODM Manufacturing for Global Brands

Tungsten • Copper • Stainless Steel • Titanium • Engineering Plastics

Shenzhen Zhucheng Technology • 深圳注成科技

Leading OEM/ODM Manufacturer

We specialize in precision metal parts manufacturing using advanced MIM, powder metallurgy, and CNC machining. Serving global brands in medical devices, automotive, aerospace, electronics, and industrial sectors with exceptional quality and reliability.

Shenzhen Zhucheng Technology Co., Ltd.

深圳市注成科技股份有限公司

Founded in 2008, Shenzhen Zhucheng Technology Co., Ltd. is a National High-Tech Enterprise and a member of multiple national standardization committees, including the National Powder Metallurgy Standardization Technical Committee, the China Text and Sports Goods Association, the China Radio Equipment Standardization Committee, the Light Weapons Equipment Committee, the National Powder Metallurgy Gold Standardization Committee, and the China Steel Powder Metallurgy Branch Injection Molding Committee.

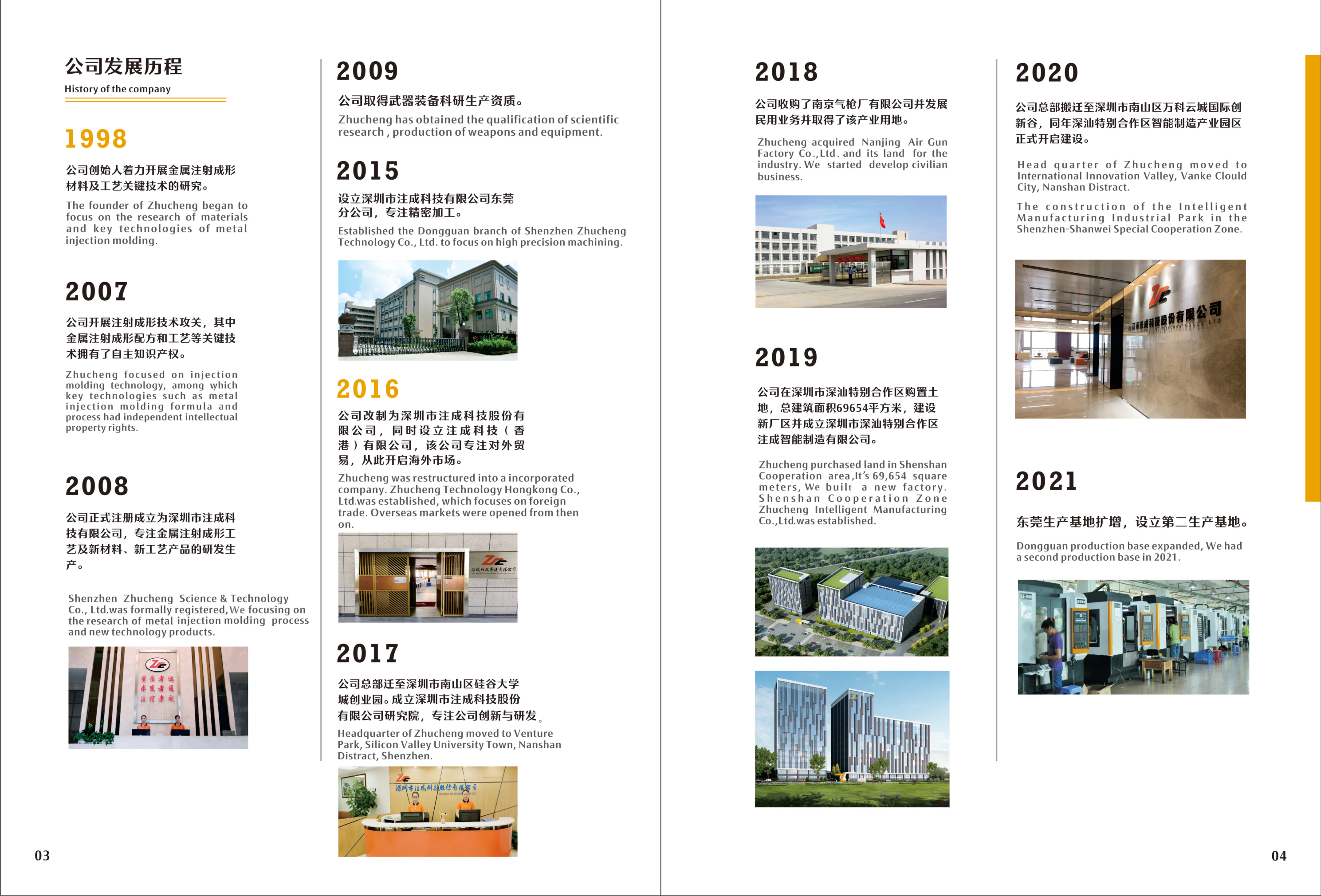

27 Years of Innovation

From 1998 to today, committed milestones across production bases, certifications, and technological breakthroughs

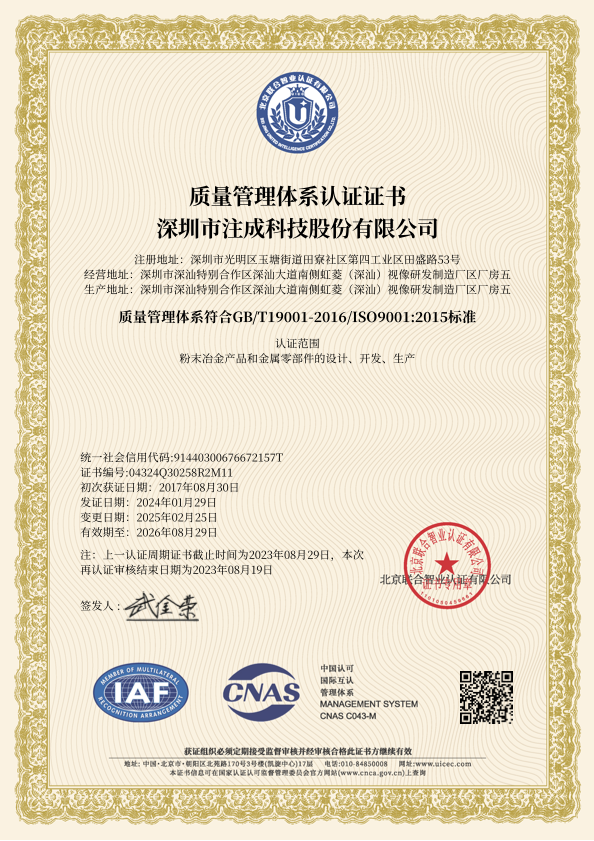

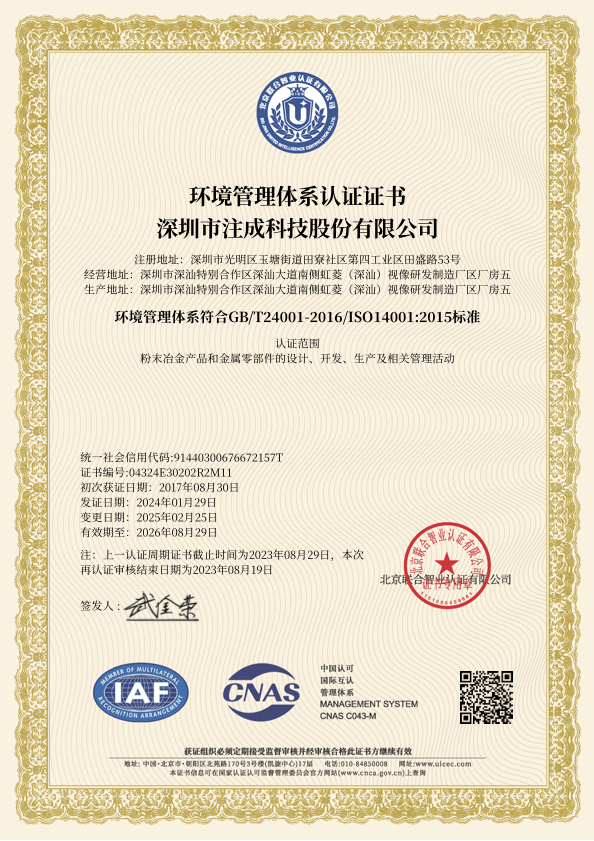

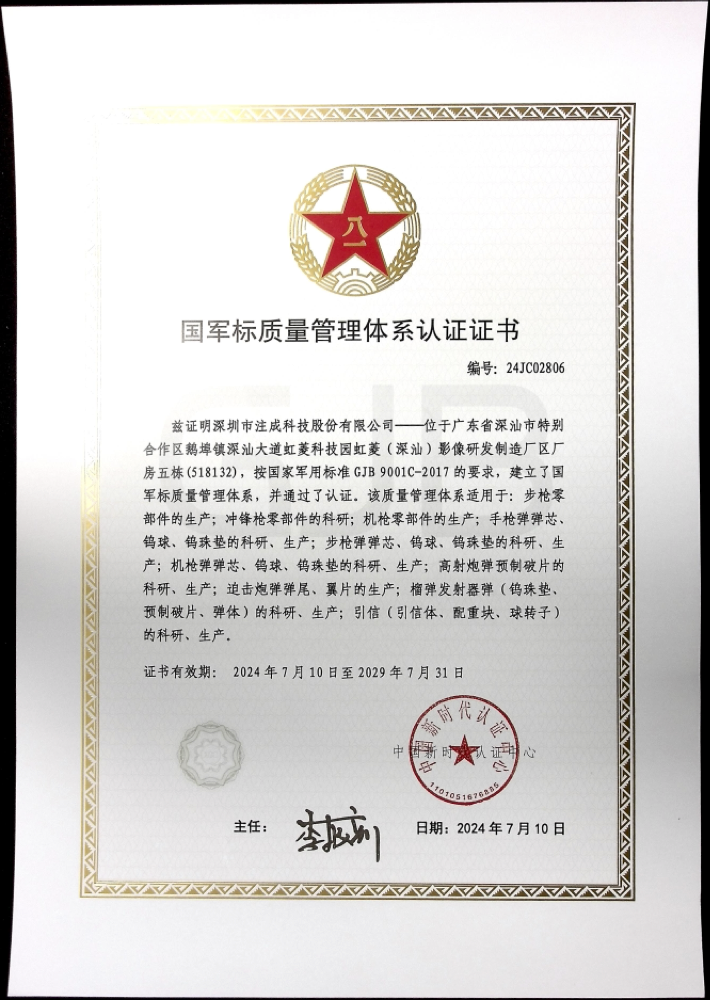

Our Certifications

Quality, environmental, and military standard certifications

Quality Management System Certificate (ISO 9001)

Environmental Management System Certificate (ISO 14001)

Military Standard Certificate (GJB)

Innovation & Patents

Our portfolio of invention patents and utility models

6.jpg)

High-Efficiency Armor-Piercing Core

.jpg)

Frangible Bullet Core and Manufacturing Method

.jpg)

Manufacturing Method for Tungsten Bead Cushion

9.jpg)

Universal Locking Device for KEYMOD and M-LOK

Manufacturing Capabilities

From raw materials to finished precision parts, we deliver excellence at every stage

Materials

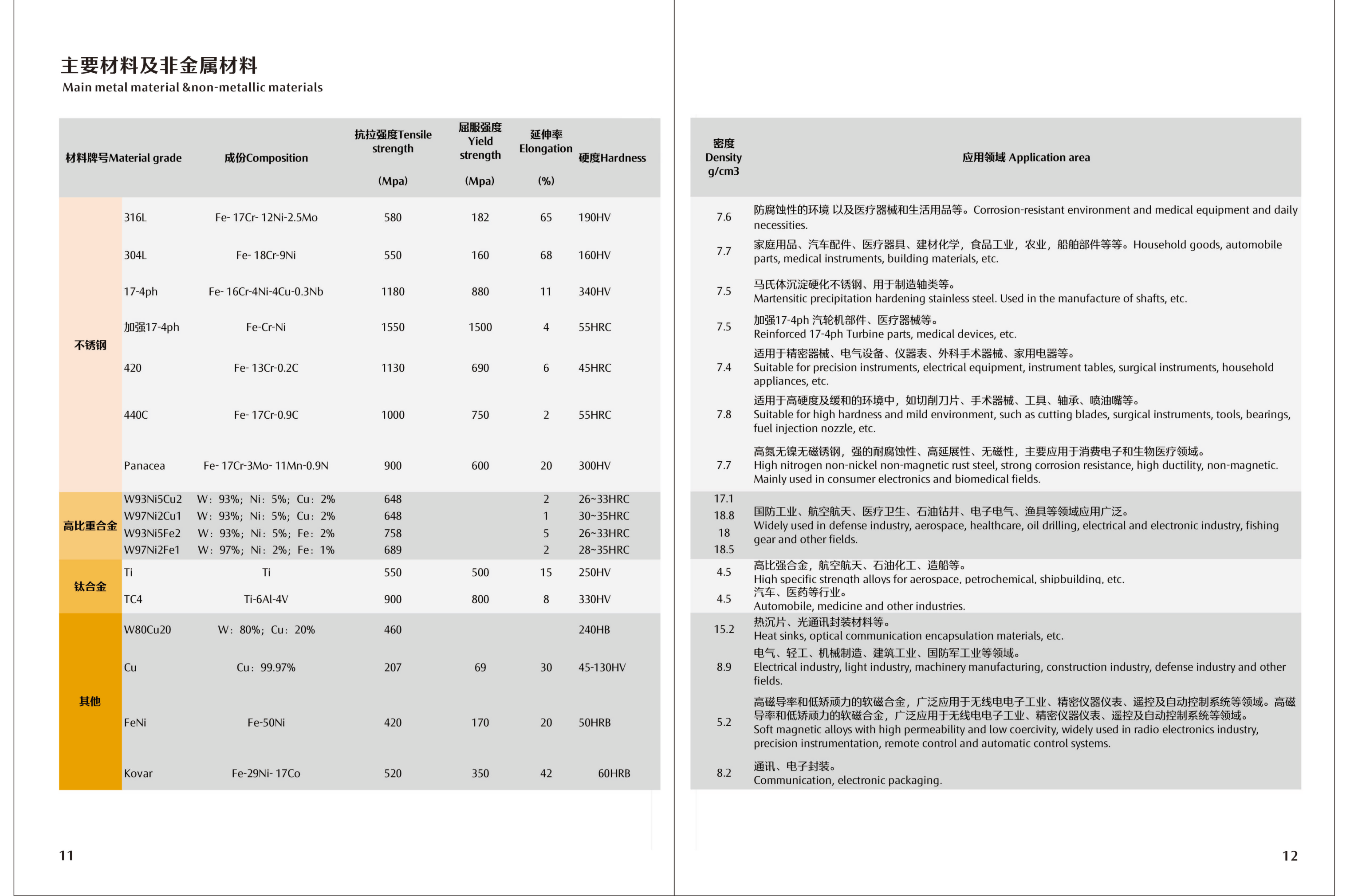

Tungsten, copper, stainless steel, titanium, magnesium alloys, and engineering plastics. Complete property sheets with tensile strength, density metrics, and application references.

Processes

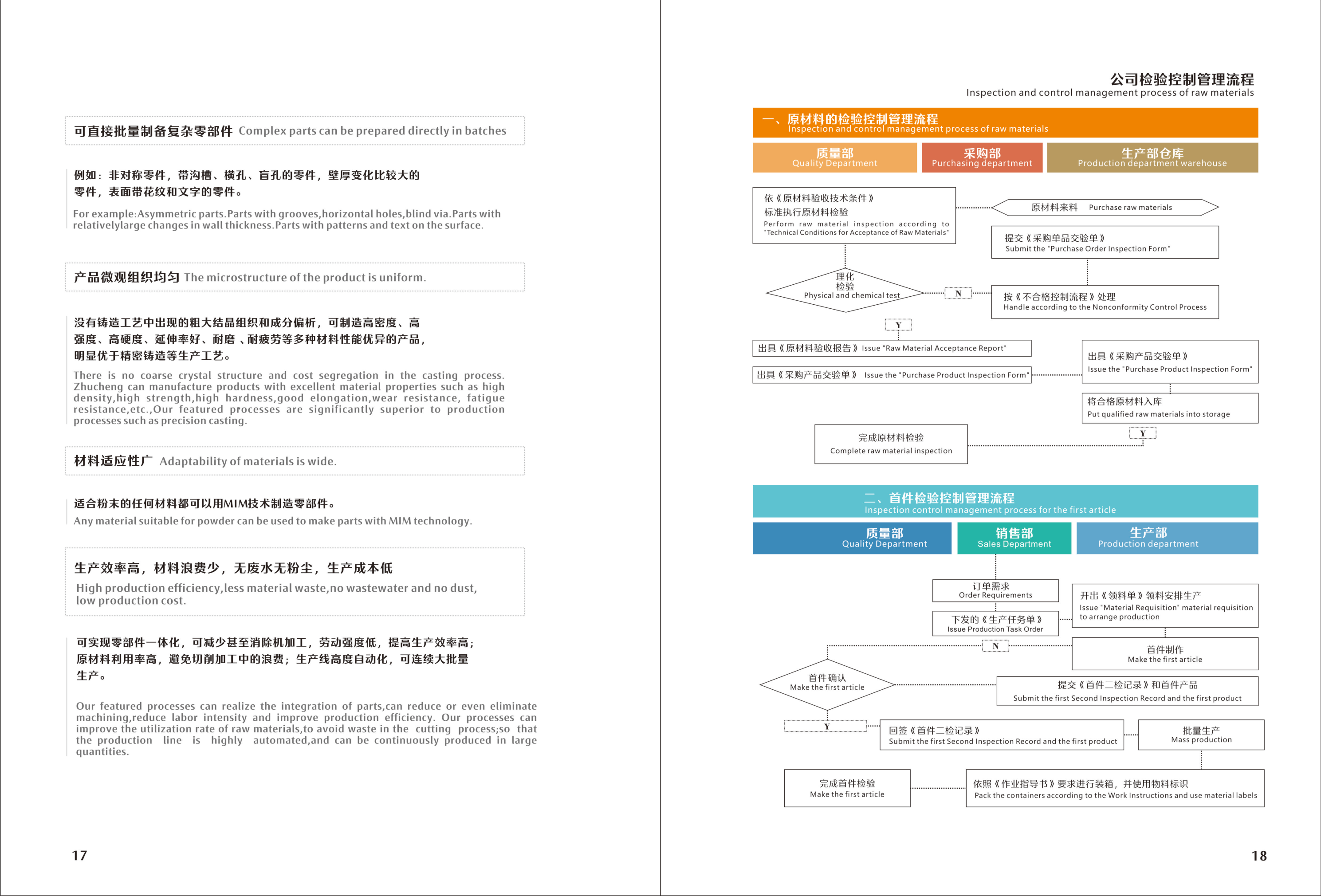

Metal injection molding (MIM), powder metallurgy, and infiltration workflows. Complete process flows from material prep to inspection with CMM and FAI/PPAP support.

Industries We Serve

Trusted by leading brands across multiple sectors worldwide

Fishing & Outdoor

High-density tungsten alloy sinkers, lures, multi-tools, archery components, and tactical accessories.

Communications

SC base-station shielding parts, precision housings, and RF component assemblies in tungsten and copper alloys.

Opto-Electronics

Heat spreaders, packaging frames, and thermal management solutions for LED and laser modules.

Medical Devices

Surgical instruments, orthopedic fixation, minimally invasive tools, and scalpel assemblies in medical-grade stainless steel.

Construction & Mining

Oil drilling nozzles, valve seats, heavy machinery inserts, and tungsten drill bits for extreme wear resistance.

3C Consumer Electronics

Laptop hinges, camera rings, earbud housings, smartwatch components, and precision fasteners.

Built on Quality & Trust

Our core values drive everything we do

匠质求达

Devote to quality improvement

Precision-crafted tungsten and alloy solutions with rigorous inspection at every stage.

求索革新

Strive for consecutive innovation

Continuous R&D investment in metal injection molding and composite material breakthroughs.

立信奋新

Keep an integrity to succeed

Trusted partnerships supported by ISO-aligned quality and responsive customer care.

Ready to Start Your Project?

Get in touch with our team to discuss your precision manufacturing needs